-

10

- Nanoelectrode System Developed to Extract Electricity from Algae

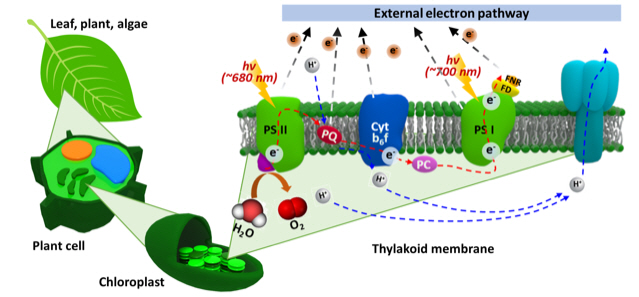

- A research team led by Professor Won-Hyoung Ryu has created a technology to extract photosynthetic electrons from algae Yonsei Mechanical Engineering Professor Won-Hyoung Ryu’s research team has created a technology to extract photosynthetic electrons from algae. Their method involves inserting a patterned nanowire or nanoelectrode into live algal cells, enabling the potential harvesting of electricity from multiple cells simultaneously. The team reported on this new energy conversion technology in the September 14, 2016 issue of Advanced Functional Materials, an important journal in the field of materials engineering. Of the research, Professor Ryu said: “The system we developed this time is a new concept of bio-solar energy conversion technology that uses algal cells, which have recently come to the fore as an environmental issue. This technology’s development is the product of a study that showed the possibility of the practical use of photosynthetic currents, and it further shows the possible development of bio-solar energy hybrid energy conversion technology.” Updated in Feb 2017 Reference Kim, L. H., Kim, Y. J., Hong, H., Yang, D., Han, M., Yoo, G., Song, H. W., Chae, Y., Pyun, J.-C., Grossman, A. R., Ryu, W., “Patterned Nanowire Electrode Array for Direct Extraction of Photosynthetic Electrons from Multiple Living Algal Cells” Advanced Functional Materials, doi: 10.1002/adfm.201602171

- 기계공학부 2020.06.27

-

9

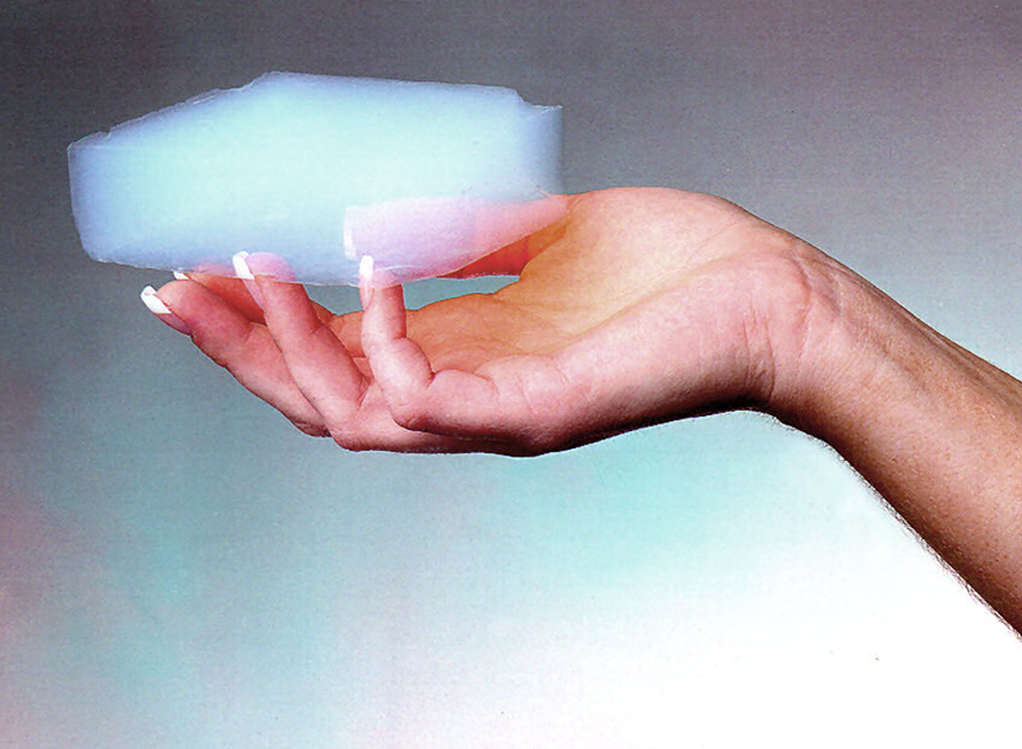

- Artificial materials for developing low-cost optical devices

- New research demonstrates macroscale materials having optical properties that are modifiable by mechanical compression, paving the way for industrial-scale production of advanced optical devices. The study—“Scalable variable-index elasto-optic metamaterials for macroscopic optical components and devices”—published in Nature Communications was carried out by a group of researchers including Dr. Kyoungsik Kim of Yonsei University. They developed a method to build large, low-cost, and mass-producible advanced optical devices by using an artificial material called “metamaterial” that changes its refractive index when subjected to mechanical stress. This material was used to demonstrate two macroscopic-scale optical devices that have so far been achieved only in the microscopic scale. These artificially engineered materials can exhibit properties difficult to observe in nature, such as a refractive index varying along the cross section of materials. So far, metamaterials have been fabricated by painstakingly shaping the microscopic structures of materials through nanofabrication techniques. Dr. Kyoungsik Kim shares, “optical metamaterials are limited to a microscopic level because nanofabrication techniques are expensive and time-consuming.” Such microscopic optical devices require artificial light couplers to interact with light, and they can only be used for a limited wavelength range. These limitations motivated the researchers to look for a simple and commercially viable solution to produce advanced optical devices. “Optical metamaterials offer a whole new range of opportunities in photonic markets as they can be produced on a large scale with affordable prices,” Dr. Kim adds. Transparent homogenous aerogel chunk capable of being compressed to obtain the desired refractive index. By Courtesy NASA/JPL-Caltech (NASA Stardust Website) [Public domain], via Wikimedia Commons In their experiments, the researchers used a synthetic, porous, and extremely light material called an aerogel. This is essentially a gel formed with air (or a gas) instead of a liquid. They made compressible, transparent, and homogeneous aerogel chunks measuring approximately 5 cm across, filled with nanometer-sized pores. The refractive index of the aerogel varies with the extent of mechanical compression, and the aerogel is transparent in the entire visible spectrum. Thus, it can be used to make optical devices with a graded refractive index, which means that the refractive index within the material continuously changes along one direction. As practical examples, the researchers demonstrated two optical devices—a transformation-optics wave bender and a Luneburg lens—using compressed aerogels. The wave bender is an arc-shaped aerogel slab that can guide light from one end to the other, whereas the Luneburg lens is a disc-shaped aerogel slab that can redirect and focus light. These devices were formed by compressing the aerogel using molds to achieve the required graded refractive index. The sizes of these components were much larger than previously developed metamaterial devices. This means that light can be manipulated in a much larger region, making artificial light couplers unnecessary. Both these optical components were shown to work well in the entire visible spectrum. For the first time, low-cost and mass-producible macroscopic-scale metamaterials were produced. The researchers say, “Our method allows natural light to interact directly with metamaterial devices without any additional coupling components, opening the door to industrial applications of optical metamaterials in general, and transformation optics in particular.” This technology is expected to lead to the industrial-scale production of adaptive lenses for advanced miniaturized cameras, machine vision, lidar-based technologies, and energy harvesting. Updated in Dec 2017

- 기계공학부 2020.06.27

-

8

- A New Infrared Stealth Technology Platform Presented

- The Yonsei research team led by Professor Jae Won Hahn develops infrared stealth technology using metamaterial. Professor Jae Won Hahn’s team (School of Mechanical Engineering, Yonsei University) has succeeded in developing the world’s first infrared stealth technology that can defend various missiles including laser guided missile and heat-traced missile. Particularly, it is expected that it will contribute greatly to the development of domestic defense technology by realizing stealth technology using metamaterials at the infrared wavelength widely used in actual weapon systems. There are two representative advanced guided missiles. One is ‘laser-guided missile’ which induces by the light reflected from the target by irradiating an infrared laser and another is ‘Infrared Search and Track (IRST) missile’ which intercepts by detecting the infrared rays emitted by the target. Infrared stealth technology is a key technology in these missile defense systems, and the metamaterial infrared stealth technology developed in this study has the feature to simultaneously defend two kinds of advanced guided missiles. Professor Hahn’s research team presented the process of designing and simply producing plasmonic metamaterials for the practical use of technology in research paper. By periodically arranging nano-sized disks and ring structures on a flexible dielectric, they realized a metamaterial that selectively absorbs infrared light according to wavelength. The metamaterial structure proposed in the study consists of a metal thin film of about 100 nanometers, a dielectric thin film, and three layers of metal insulator metal (MIM). Various applications are possible by fabricating on a thin dielectric substrate or block type tile surface. It can be used for defense of military base facilities as well as air navigation devices including tanks, jeeps, ground transportation vehicles, and helicopters. Once the flexible dielectric mass production technology is secured, it can be applied to the development of infrared camouflage military uniform that is not detected by the infrared detection device by applying the meta-material to the coating. The results of this study are of great academic significance in that it presented a new infrared stealth technology platform. Further, it is expected that it will contribute to technology independence and advancement of advanced defense system of domestic defense industry as it developed the original technology that can be used as actual military technology. The results of this study, which was supported by the Defense Acquisition Program Administration and Agency for Defense Development, were published in the online edition of Scientific Reports, a worldwide international journal on July 27, and domestic and foreign patents were applied for related technology. Updated in Jan 2018

- 기계공학부 2020.06.27

-

7

- Yonsei Develops World’s First Smart Invisibility Cloak

- The Optical Metamaterial Laboratory, led by Prof. Kim Kyoung-sik (Mechanical Engineering), is the world’s first to theoretically propose smart metamaterials and experimentally succeed with a smart invisibility cloak. Due to its use of material with heterogeneous structures in fixed condition, the existing invisibility cloak has shown a number of drawbacks, including losing its features, as with compression or tensile deformation, and taking long hard hours to make an invisibility cloak in a smaller size. The Laboratory’s recent study designed and produced a smart elastic photonic crystal structure that fulfills the unified changes of solid materials’ elastic deformation and optical metamaterials’optical deformation. This structure enables the production of an invisible cloak, maintaining the properties of the cloak regardless of its change in shape, as shown in science fiction films. The study also succeeded in creating the world’s first invisibility cloak made with a homogeneous photonic crystal structure. This has brought us a step closer to mass production of such a flexible largearea invisibility cloak. Their study, entitled “Broadband electromagnetic cloaking with smart metamaterials” (corresponding author: Prof. Kim Kyoung-sik; first author: Shin Dong-heok), was published on November 20, 2012 in the online edition of Nature Communications, a sister publication of the world’s leading scientific journal Nature. One of the co-authors of the study was Prof. David Smith (Duke University), the first to develop an invisibility cloak and refractive index metamaterials and who has been named in the media as a potential candidate for the Nobel Prize in Physics. Also, corresponding author Prof. Kim Kyoung-sik published a joint research article in Physical Review Letters in 2007 with that year’s Nobel Prize winner in Physics, Prof. David Wineland (United States National Institute of Standards and Technology, NIST). Prof. Kim Kyoung-sik said, “As a master’s and doctoral student, I majored in Particle Physics Theory and Optics. I got to apply elastic solid mechanics to optics as I began to work in Mechanical Engineering. I am very pleased to get such positive results.” He added, “Metamaterial technology can be variably applied to a wide range of such functional devices as optical lithography, stealth technology, optical material, thermal material, and high-efficiency energy material.

- 기계공학부 2020.06.27

-

6

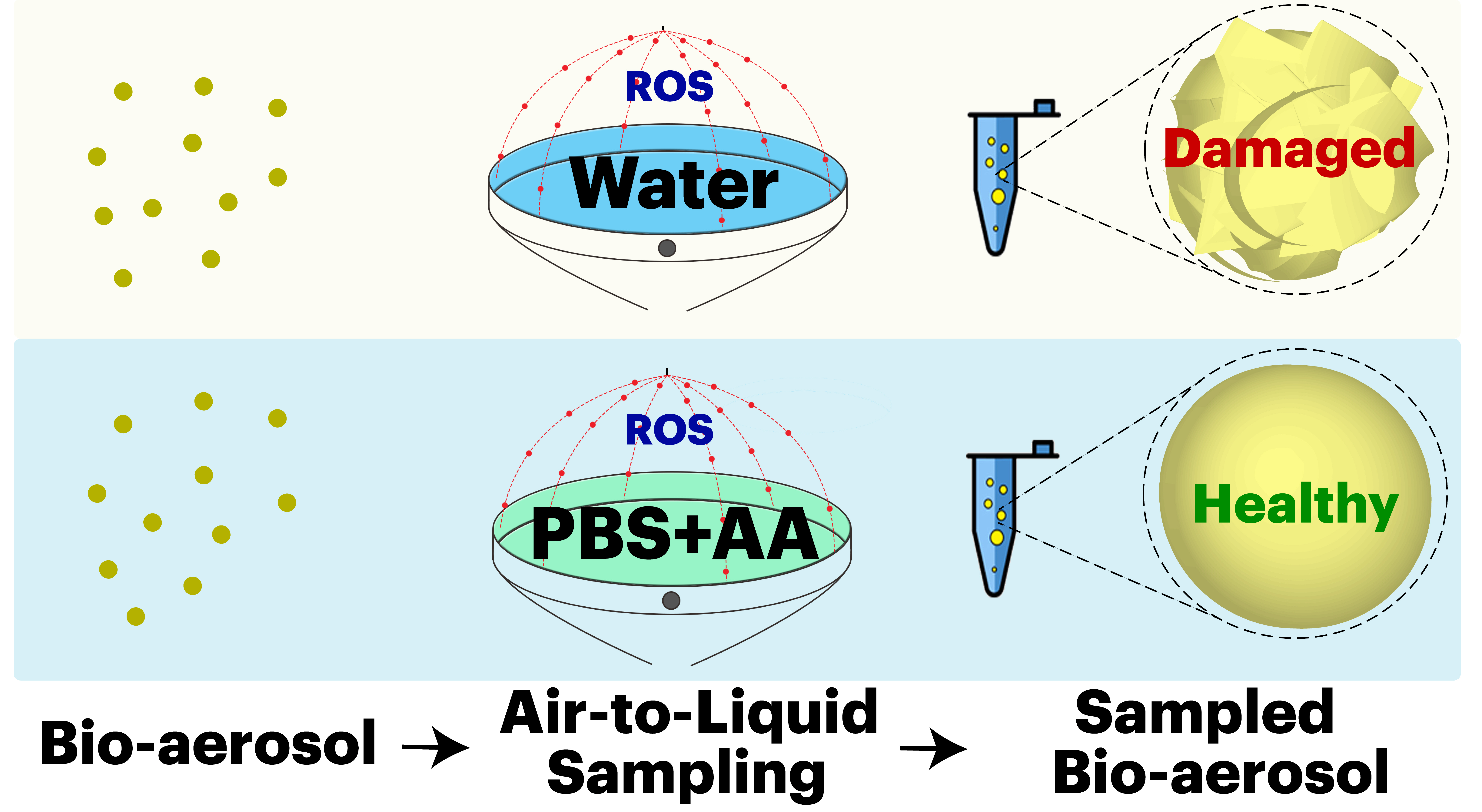

- Development of In-situ Air Samplers for Real-time Airborne Virus and Bacteria Monitoring

- Development of In-situ Air Samplers for Real-time Airborne Virus and Bacteria Monitoring A Yonsei research team, led by Professor Jungho Hwang in the school of Mechanical Engineering has been developing various techniques for real-time sampling of airborne pathogenic bioaerosols such as bacteria and virus. The air samplers are designed for an efficient collection of bioaerosols in either hydrosols or non-hydrosol-based platforms. The air samplers are integrated with various detection systems to provide rapid and accurate detection. The intracellular substance of bacteria collected by the air samplers reacts with a luminescent reagent to emit light, and the intensity of this light is proportional to the number of bacteria. The air samplers can also collect airborne viruses that are assayed using a commercial in-vitro diagnostic kit. The team has also elucidated an efficient technique for reducing the bioaerosols damage during aerosol-to-hydrosol sampling process. The results of these studies have been published in J. Hazardous Materials and Analytica Chimica Acta. According to Professor Hwang, “Bioaerosol sampling is crucial for environmental monitoring of hazardous airborne pathogens, which can contribute greatly to global health concerns and possibly prevent future pandemics.”

- 기계공학부 2020.06.08

-

5

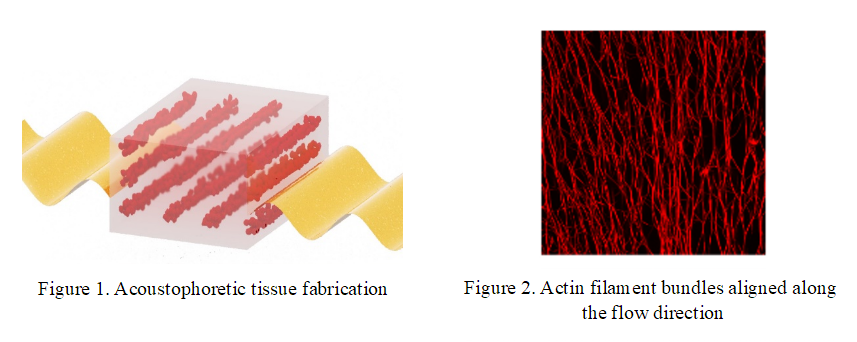

- High-resolution Acoustophoretic Engineering

- High-resolution Acoustophoretic Engineering Mechanobiology and Soft Material Laboratory at Yonsei University led by Prof. Hyungsuk Lee develops the acoustophoretic technique that apply to manipulate kinds of particles and cells. With the advantages of non-invasiveness, no need of label, and energy efficiency, the technique is able to select, pattern, mix, and translate micro-sized objects. Recently, the technique was used to fabricate a vascular tissue construct consisting of a biocompatible hydrogel and co-aligned multi-type cells in 3D patterns. The fabricated tissue replicating the tissue-specific cellular arrangement exhibited improvements in terms of differentiation, maturation, and anti-inflammation response of tissue. Implantation of the engineered tissue recovered the perfusion rate remarkably and rescued the ischemic tissue ultimately. The results of the research were published in Nature Communications with the title of “High-resolution acoustophoretic 3D cell patterning to construct functional collateral cylindroids for ischemia therapy”. The acoustophoretic technique can be further developed as a high-resolution bioprinting method to create any types of tissues, which are essential for tissue regeneration, therapeutic, and drug screening applications. 1. Kang B, Jo S, Baek J, Nakamura F, Hwang W, Lee H. Role of mechanical flow for actin network organization. Acta Biomaterialia, Vol. 90, P.217-24, 2019 2. Kang B, Shin J, Park HJ, Rhyou C, Kang D, Lee SJ, Yoon YS, Cho SW, Lee H. High-resolution acoustophoretic 3D cell patterning to construct functional collateral cylindroids for ischemia therapy. Nature Communications, Vol. 9, P. 5402, 2018

- 기계공학부 2020.06.08

-

4

- Micro sensors for accurate on-site monitoring of airborne nanoparticles

- Micro sensors for accurate on-site monitoring of airborne nanoparticles For accurate monitoring of airborne nanoparticles at a point of care, a Yonsei research team led by Professors Kim, Yong-Jun developed micro nanoparticle detection sensors. These sensors grow nanoparticles to micrometer droplets in the chip through condensation, and count grown droplets based on the light scattering method. Using this measurement principle, the sensors were able to count individual nanoparticles as small as 10 nm, guaranteeing accurate measurement performance. Moreover, since the essential functions for growing droplets are integrated on a single chip using semiconductor manufacturing process, the sensors are far cheaper, smaller than the conventional nanoparticle instruments. According to professor Kim, the sensors can be readily used in any kinds of environments where on-site monitoring is required, such as indoors, outdoors or work places. Also, they can be applied to the assessing individual daily exposure to nanoparticles, contributing to the undergone exposome projects including ‘The Human Early-Life Exposome (HELIX)’. The results of the research were published on 2018, November 5 as the article of the Atmospheric Measurement Techniques, and 2020, March 1th as the article of RSC Lab on a chip. (Link to the paper) Figure 1: The two types of micro nanoparticle detection sensors; left one generate droplets using butanol vapor (Atmos. Meas. Tech., 12, 5335–5345, 2019), and the other is based on water vapor (Lab Chip, 2020, 20, 1092). The essential components for growing droplets on the chip, which are integrated on the single chip using the semiconductor manufacturing process. Figure 2: On-site monitoring results of the sensors, compared with the reference instrument.

- 기계공학부 2020.06.08

-

3

- Photosynthetic Bio-solar Cells: Electricity from Plants and Photosynthetic Algal Cells

- Photosynthetic Bio-solar Cells: Electricity from Plants and Photosynthetic Algal Cells Natural photosynthesis is the cleanest energy conversion process by which solar energy is converted to electricity with high efficiency. A team led by Prof. WonHyoung Ryu in Department of Mechanical Engineering has been investigating engineering methods to directly extract photosynthetic electrons (PEs) from living plant cells, algal cells, and isolated photosynthetic membranes or apparatus. The team has developed nanoscale electrodes (NEs) to penetrate cell membrane and directly extract PEs from living algal cells, including a cantilever NE system for single cell analysis (Nano Res. 2018), vertically-aligned NE array for multiple cells insertion (Adv. Funct. Mater. 2016), or highly-dense NE arrays for cell film insertion (Biosens. Bioelectrons. 2018). Recently, the team started using thylakoid membranes (TMs) isolated from spinach leaves to construct photosynthetic anodes for enhanced PE extraction using various nanomaterials using CNTs, metallic nanoparticles, graphene oxides. Currently, as an effort to develop the technology to practical systems, the team also started building photosynthetic bio-solar cells with an aim to power small ICT sensors.

- 기계공학부 2020.06.08

-

2

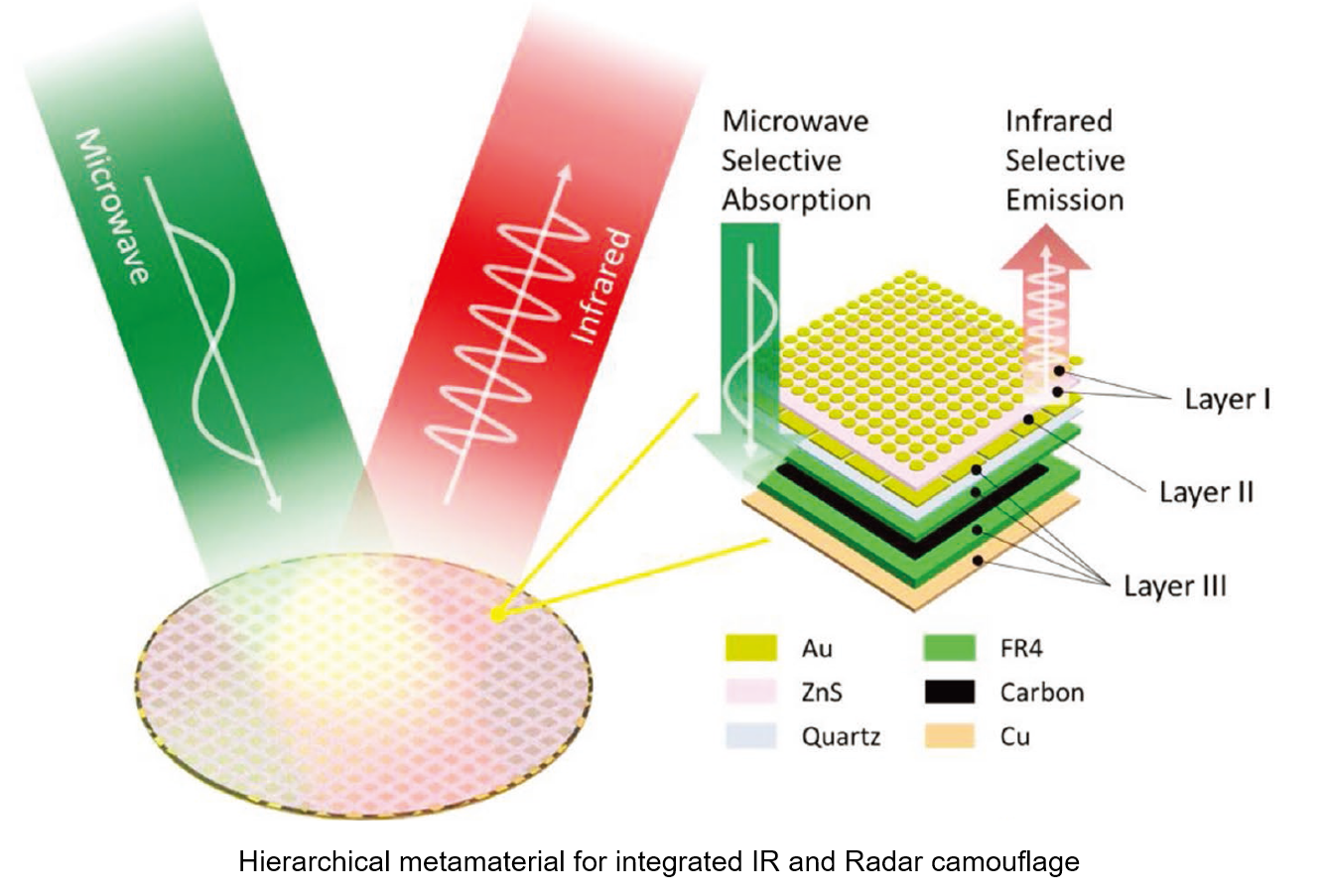

- Develops Hierarchical Metamaterial For Multispectral Camouflage

- Develops Hierarchical Metamaterial For Multispectral Camouflage Professor Hyung Hee Cho in School of Mechanical Engineering and his research team have developed the world’s first hierarchical metamaterial for integrated infrared and radar camouflage. Camouflage technology is a state-of-the-art technology that enhances national defense by protecting its military assets from detection systems. Since the detection system detects the wavelength of a specific band, camouflage technology has been developed as to deceive the detection system by adjusting the optical and thermal characteristics of surfaces. However, it is difficult to control radar and infrared waves at the same time. This is because the scale difference of surface for radar and infrared camouflage was more than 1000 times. However, Professor Cho mediated the IR selective emitter for IR camouflage with a microwave selective absorber for radar camouflage through a high-frequency filter. The results of the research were published in March 2019 as the cover article of Advanced Functional Materials with the title “Hierarchical Metamaterials for Multispectral Camouflage of Infrared and Microwaves” and US and Korea patent with the title “Composite Structure for Controlling Absorptivity of Radar And Emissivity of Infrared Regions” have been registered.

- 기계공학부 2020.06.08

-

1

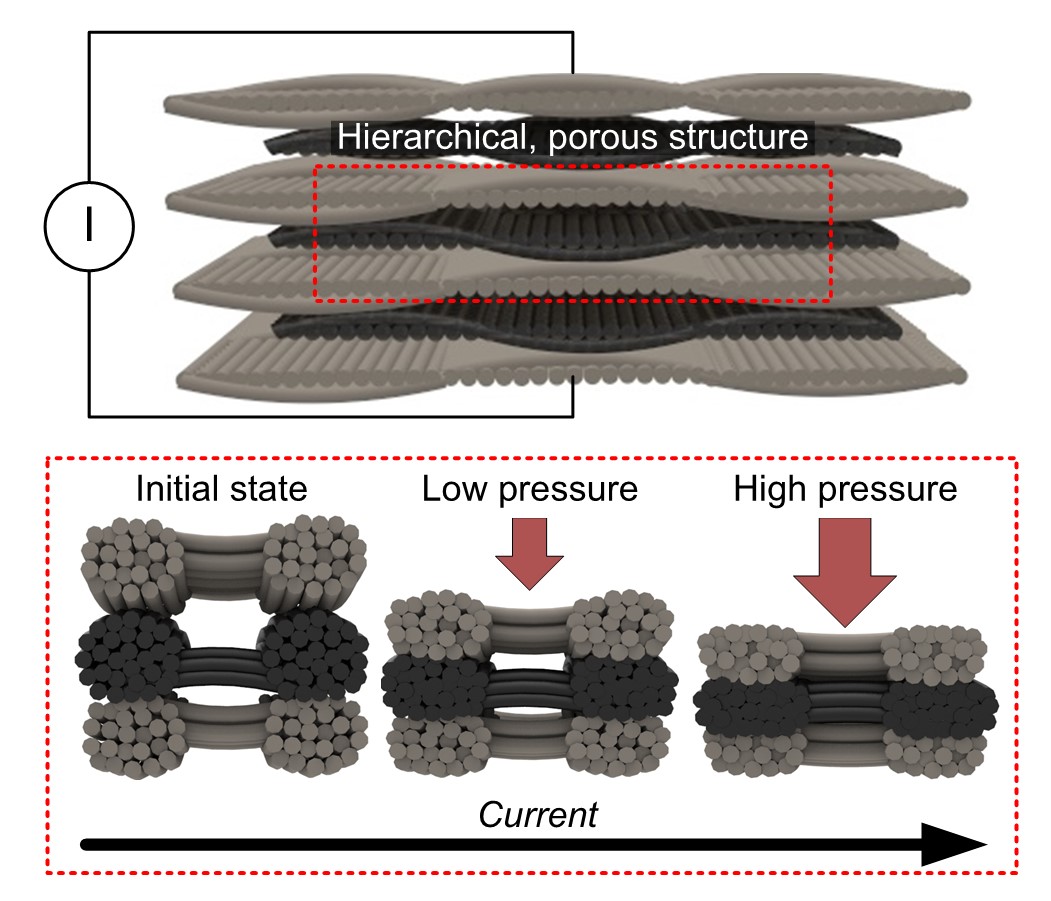

- Advancing flexible tactile sensors for interfacing human and machine

- Advancing flexible tactile sensors for interfacing human and machine Professor Jongbaeg Kim and his research team at Yonsei have developed high-performance flexible tactile sensors for advanced wearable applications. The researchers utilized nanomaterial-coated fabrics as sensing materials and stacked them into multilayers to maximize their structural benefits, which dramatically enhanced sensing performances. The team also demonstrated all-textile flexible keyboards and wearable tactile interfaces that wirelessly deliver tactile information between the users, proving the potential of their work. These results were published as the cover article of Advanced Functional Materials in August 2019, with the title “Multi-Layered, Hierarchical Fabric-Based Tactile Sensors with High Sensitivity and Linearity in Ultrawide Pressure Range.” Professor Kim and his team have been working on flexible electronic devices through advanced materials and designs. They have been developing 1) functional devices such as multidirectional force sensors and crosstalk-free sensor matrices, and 2) fabrication technologies for integrating high-performance sensors into flexible platforms. With these technologies, the team aims to realize multimodal interfaces that can bridge the gap between human and machine. According to Professor Kim, their research “may be applied to augmented/virtual realities and wearable robots by providing enhanced haptic interaction and delicate control.”

- 기계공학부 2020.06.08